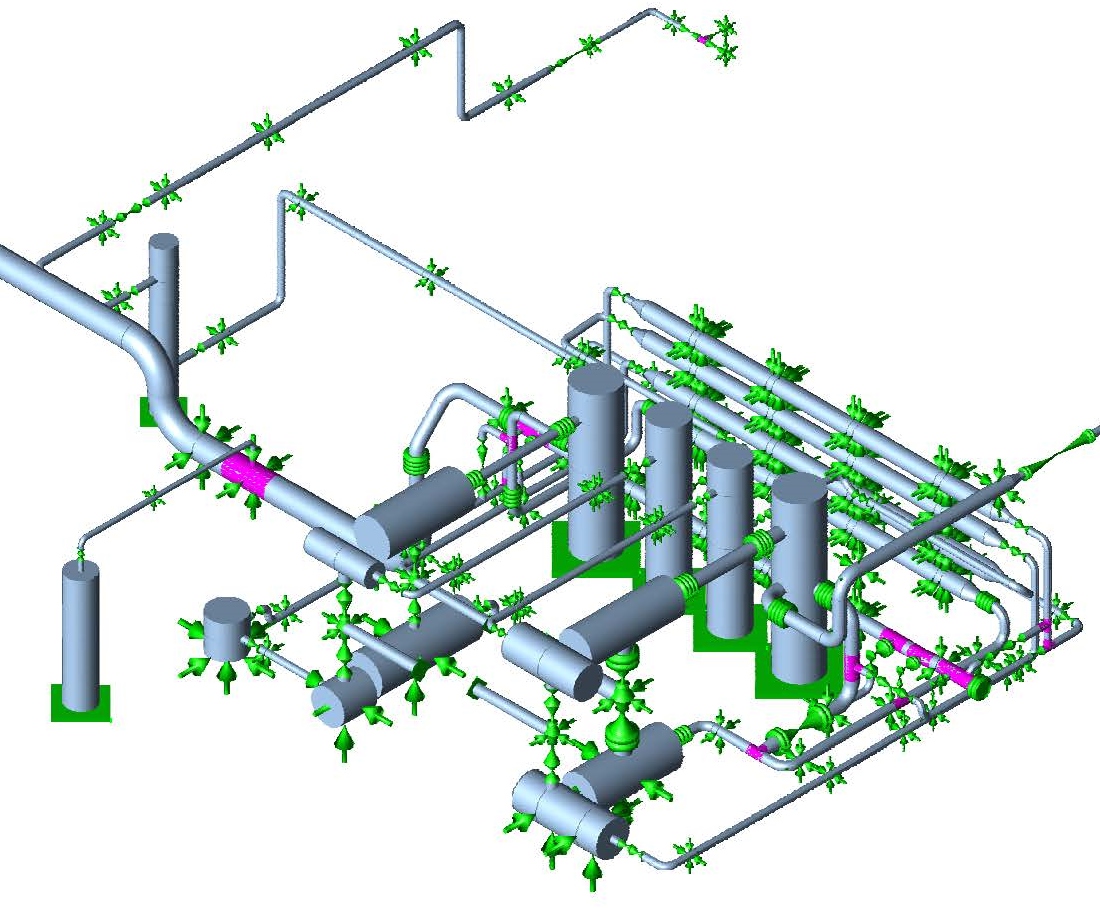

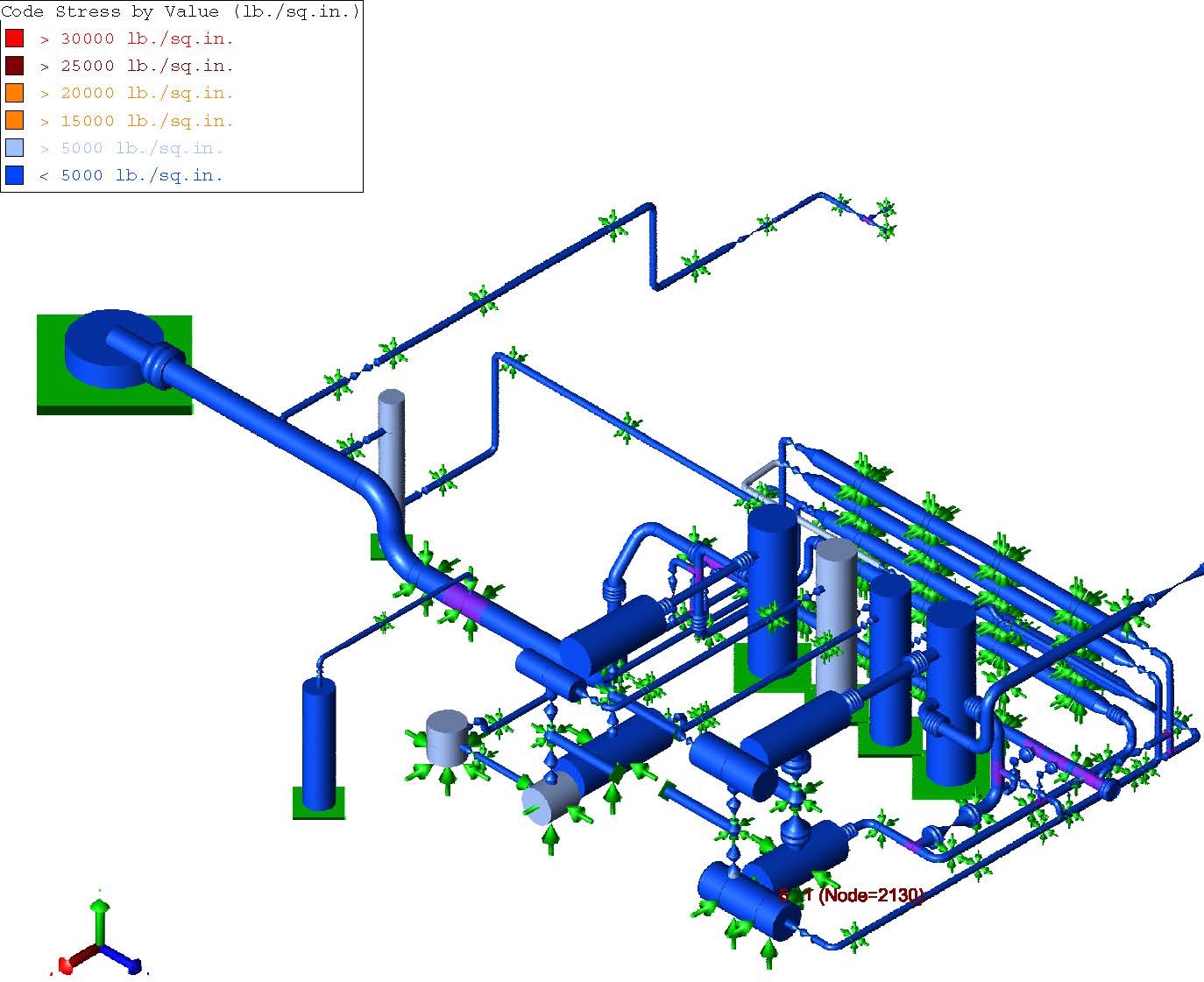

Pipe Stress Analysis

Pipe stresses include everything from thermal growth to pipe support stiffness and more.

Pipe stresses include everything from thermal growth to pipe support stiffness and more.

This study includes calculating stresses from thermal growth, pressure, and weight of the piping system. The sum of these results is compared to meet API or ASME standards. Upon completion of the analysis, Compression Dynamics will recommend pipe layout, pipe support and clamp designs. This study is particularly important for reciprocating compressor facilities especially when the cooler is remotely located from the compressor (the long lengths of hot piping may experience high thermal stress), systems with high discharge temperatures, or systems with extreme ambient conditions.

Piping designers traditionally route piping by layout, process, flow constraints (such as pressure drop) and other constraints but often do not take vibratory service into consideration. Pipe stresses are often not sufficiently considered while routing and supporting dynamics piping systems, especially when providing adequate flexibility to absorb thermal expansion/contraction of pipes. Upon completion of this analysis, Compression Dynamics will present you with proper modifications to bring piping systems into API or ASME codes.